Discover the Potential: Materials Test Lab Insights for Success

Wiki Article

Accuracy Screening of Materials for Toughness and Toughness

Accuracy screening of materials for stamina and toughness plays a vital role in various sectors, including construction, manufacturing, and engineering. This process involves subjecting different materials to strenuous analyses to establish their ability to withstand outside pressures and preserve their integrity in time.On the planet of materials testing, precision is extremely important. Designers and researchers count on accurate and reputable information to make informed choices concerning product option, design optimization, and item efficiency. By utilizing sophisticated testing methods and advanced equipment, professionals can evaluate the strength and sturdiness of a wide variety of materials, such as steels, polymers, composites, and ceramics.

This introduction will certainly give understandings right into the importance of accuracy screening, the kinds of products commonly based on testing, the essential specifications for strength analysis, and the strategies utilized for toughness analysis. It will additionally highlight the applications and advantages of performing accuracy testing in different markets.

Significance of Accuracy Testing

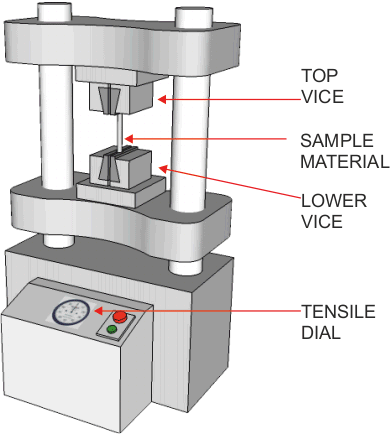

Precision testing is a crucial action in assessing the stamina and toughness of products, supplying exact and trustworthy data for notified decision-making. The top quality and performance of products play an essential duty in making certain the security and long life of structures and items when it comes to production and construction markets. Performing accuracy screening is of utmost importance to identify whether the materials satisfy the needed specifications and standards.By subjecting materials to strenuous screening designers, procedures and suppliers can evaluate their mechanical homes, such as tensile toughness, solidity, and influence resistance. This info allows them to guarantee that the materials can stand up to applied forces and environmental conditions without failing or deterioration gradually. Furthermore, precision testing aids identify any possible problems or weaknesses in the products, making it possible for manufacturers to make required improvements or modifications to boost performance and dependability.

Additionally, accuracy testing gives quantifiable and objective information that can be made use of to contrast different materials and make informed choices about their viability for details applications. When picking materials for crucial parts or frameworks where failure can have serious consequences., this info is specifically valuable.

Sorts Of Products Subjected to Testing

Numerous materials undergo testing for strength and resilience. This screening is important to ensure that the materials can withstand the needs of their desired applications and to identify their anticipated life expectancy. The kinds of materials subjected to testing are varied and include metals, polymers, porcelains, compounds, and building products.Metals, such as steel and aluminum, are typically tested for their tensile strength, solidity, and resistance to deterioration. materials test lab. These examinations aid determine their viability for usage in structural applications, equipment, and various commercial processes

Ceramic materials, such as porcelain and ceramic tiles, are examined for their compressive toughness, heat resistance, and sturdiness. These tests make sure that ceramics can endure severe settings and high temperature levels, making them appropriate for applications in the construction, electric, and aerospace markets.

Composites, which are products made from a combination of various elements, are subjected to various tests to analyze their mechanical homes, such as stamina, effect, and rigidity resistance. Compound materials are widely used in sectors such as aerospace, vehicle, and sports equipment manufacturing.

Construction products, consisting of asphalt, wood, and concrete, go through testing to establish their load-bearing capability, resilience, and resistance to weathering. These examinations are crucial in making certain the security and durability of bridges, frameworks, and roadways.

Secret Specifications for Toughness Evaluation

One of the crucial parameters for stamina analysis is the tensile strength, which determines a material's capability to stand up to drawing forces without damaging or warping. Another essential specification is the compressive toughness, which reviews a material's resistance to crushing or being squeezed together. By examining these crucial parameters, scientists and designers can accurately evaluate the stamina and durability of materials, enabling them to make educated choices in different markets such as aerospace, vehicle, construction, and production.

Techniques for Toughness Assessment

Longevity assessment methods are necessary for assessing the lasting performance and reliability of products. These methods are crucial in establishing the ability of products to stand up to various environmental problems and mechanical stresses over expanded amount of times. One generally utilized method is accelerated aging, which includes subjecting products to increased environmental problems such as heats, humidity, and UV radiation. This enables scientists to imitate the results of long-term exposure in a much shorter duration, enabling them to analyze material deterioration and forecast its efficiency in time.One more technique is cyclic screening, which entails subjecting products to duplicated loading and discharging cycles. This aids review the product's exhaustion resistance and its capacity to endure repeated tension without failure. By examining the stress-strain response of the material during cyclic testing, scientists can recognize prospective weak factors and examine the material's longevity.

Furthermore, non-destructive testing methods such as ultrasonic testing and infrared thermography can be employed to analyze the inner stability and identify any kind of flaws or damage in the product. These methods supply important info regarding the product's longevity without creating any type of damages to it.

Applications and Benefits of Precision Screening

Precision screening plays a vital duty in examining the stamina and resilience of materials, enabling engineers and researchers to obtain reputable and precise data for reviewing their performance. The applications of accuracy testing are comprehensive and can be found across numerous markets, consisting of aerospace, automobile, building, and manufacturing.Among the essential benefits of precision testing is its capability to identify prospective weaknesses or flaws in materials. By subjecting materials to regulated and extensive screening, any type of susceptabilities or defects can be spotted have a peek at these guys before they result in tragic failures. This enables suppliers to make required enhancements or adjustments to boost the general quality and resilience of their items.

Precision testing likewise Full Report assists in determining the optimum layout and composition of materials. By testing different variations and setups, designers can identify one of the most ideal materials for particular applications. This causes boosted efficiency, performance, and cost-effectiveness in different sectors.

Furthermore, precision screening gives valuable data for the development and improvement of materials and producing procedures. materials test lab. It permits researchers to acquire a deeper understanding of material habits under different problems, bring about the growth of brand-new products with boosted performance, sturdiness, and strength characteristics

Conclusion

In conclusion, accuracy testing plays a crucial function in examining the stamina and resilience of products. By subjecting various types of materials to extensive testing, crucial criteria for stamina assessment can be recognized.Precision screening is a crucial action in assessing the stamina and resilience of products, offering dependable and precise information for educated decision-making.Different products are subjected to screening for strength and sturdiness. The kinds of materials subjected to testing are diverse and include steels, polymers, porcelains, composites, and building materials.

By evaluating the stress-strain feedback of the product see here during cyclic testing, researchers can identify potential weak points and assess the material's toughness.

In verdict, accuracy screening plays an essential role in assessing the stamina and resilience of materials.

Report this wiki page